Colour Coded Cleaning – Preventing Cross Contamination...

Why is colour coded cleaning so important? Does it really make a difference?

Colour coding your cleaning equipment is an easy and helpful system to have in place in a working environment. It can be vital whilst cleaning, as it is very effective against cross contamination there are basic guidelines put in place by BICSc (British Institute of Cleaning Science) to ensure your workplace is the safest it can be. In this blog, I will explain why colour coded cleaning is so important and how to colour code your equipment correctly in hope it helps you guarantee safety for you and your employees.

What is colour coded cleaning?

To the eye, a room could look clean after a quick hoover and mop. But is it clean? Colour coding is a simple way to lower the risk of invisible contaminants such as germs and bacteria. Because of this, if you do not use a colour coding system it may be doing more harm than good. This cleaning system is commonly used throughout a variety of industries and trades.

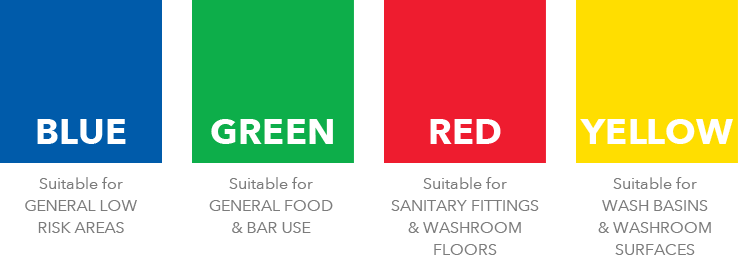

To colour code your cleaning equipment you need to designate a colour to a certain area. Each area should be appointed a mop, mop bucket, a coloured handle, dustpan and brushes, the same colour as the bucket and handle. When using a colour coding system, typically these four colours are used - red, green, blue and yellow. There are different colours for different areas to ensure you are not using the same cleaning equipment to clean your kitchen that someone else may have used to clean the bathroom. Colour coding can be broken down into four areas:

- Public areas – lobbies, receptions, seating areas etc.

- Washrooms and toilets – includes showers, bathrooms

- Restaurant and bar – dining area, café, longue/seating areas

- Kitchen and food preparation areas – any kitchen, food stations or areas where food is kept

Each colour in the colour coding system has its own purpose, the staff may decide on what colours are more suitable as long as your employees or the individuals who will be using this equipment are aware of this. In most situations, Blue would generally be used for low risk areas, such as public areas – corridors, lobbies, waiting rooms. Again, Green is for kitchen/bar areas, food preparation and round about the areas food is kept. Red is often used in washrooms – showers, baths, toilets etc. Lastly, Yellow is for bathroom sinks and surfaces, areas around the sinks and wiping down dispensers for example.

Why is colour coding so useful?

When carrying out cleaning tasks, as you can imagine using the same equipment can spread bacteria quickly, especially cross contamination. Applying a colour coded system is one of the most efficient and effective ways of reducing the risk of cross contamination or any bacteria being spread!

It is vital that everyone who is using or who may use these cleaning products/materials know what equipment is designated to what area. To help guide these people, posters are a friendly and useful reminder to have on display. It is crucial to know that under no circumstances should any chosen equipment go near an area that isn’t assigned to that particular equipment.

Watch Anna's Vlog here!

Colour coding is usually found in a workplace e.g. restaurant, bars, schools. This is because, to remain open and functioning, business type places have certain rules in place to make sure health and hygiene are all as safe as possible. As mentioned previously in this blog, BICSc are responsible for these particular guidelines, here are some tips that they provide on how to ensure that you do this effectively:

1. Making sure there has been thorough training given to all employees whether it be part of an induction or a continuous training programme.

2. It is essential that staff easily understand the colour coding system and it is simple and effective to use

3. A substantial amount of people are colour blind in one or more colours. Some individuals may not know this, and colour identification testing should form part of any induction training

4. When it comes to physically cleaning, BICSc have one golden rule. Always work from the cleanest area toward the dirtiest area. This drastically reduces the risk of cross contamination, which is one of the main aims when using colour coded cleaning

Environmental health are extremely strict when it comes to colour coding, when they pay a visit one thing they will always want to see is the presence of posters which clearly indicate you have this cleaning regime in place. They will also ask to see all your cleaning equipment, colour coded mops/buckets/cloths/rubber gloves, everything! This puts them at ease straight away, as it shows them you have a clear understanding of what you need to be doing when it comes to colour coded cleaning.

Do I have to use colour coding?

There is no legal requirement set in place that says you must use this cleaning system. However, COSHH (Control of Substances Hazardous to Health) holds you responsible for risk assessment and prevention or control of exposure to them in the work place. Colour coded cleaning is one way you can do this.

At Astral Hygiene we sell a range of colour coded cleaning equipment, to view our full range click here